In the 45 years since the first introduction of fabric-based air dispersion technology the concept has been developed and refined, but the primary differences between fabric and metal-based HVAC/R solutions are still founded on comfort, hygiene, efficiency and savings.

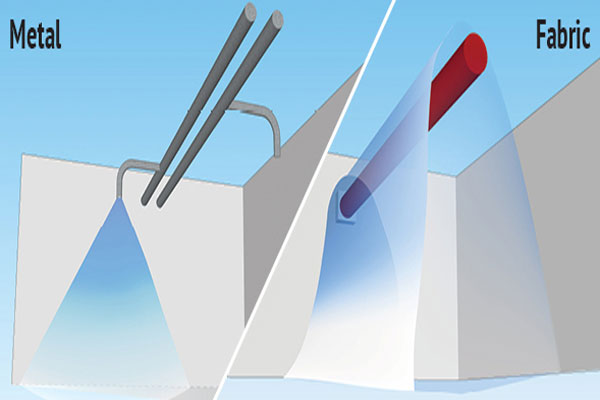

Conventional metal ducting uses spot diffusion, which creates stagnant air zones, unpleasant drafts and inconvenient noise pollution. From a comfort perspective this is the primary difference between metal solutions and FabricAir dispersion technology.

From a hygienic perspective, the condensation-free nature of fabric ducts diminishes the risk of microbial growth inside or on the ducting. Specific fabrics even have Cleanroom 3 certification. The fabrics are created in woven polyester fibers, which ensures that the ducts can be washed, even sterilized in an autoclave, without causing negative impact on their performance.

The initial advantage of fabric air dispersion technology was twofold: Eliminating drafts created a more healthy work environment, thus lowering the number of absences; and creating better airflow patterns resulted in a more even air distribution and lower temperature gradients in the meat processing plants where the technology was first applied. The latter has been an area of thorough research, which had led to a wide array of flow models that can be combined to optimize induction in any given project. This is part of what makes the technology more efficient than conventional metal solutions.

Surface flow models enable high air changes at low velocity, which is good for low ceiling applications and comfort. Directional flow models enable precise longer throws to create better induction in e.g. industrial production or high storage applications. May applications require unique combinations of airflow patterns to create the ideal air dispersion solution and using fabrics this is a straightforward creation process.

Through the use of proprietary 3D software and CFD modelling, air engineering experts design a solution specifically for a given project optimizing the airflow patterns based on the relevant parameters of the application and project specifics. Once the drawings are approved by the customers, the duct solution is tailored and shipped, arriving on site typically in less than 14 days, ready to install. This is another significant difference and an important efficiency aspect; the quickest lead times on the market.

Ease of installation is a hallmark of the technology. Instead of juggling huge, heavy steel duct pieces, the installer simply screws the rail onto the ceiling and slides the fabric ducts in place. No need for on-site attenuation, no grills or diffusors, no insulation or painting and no need for balancing. Installing a fabric-based solution is four to five times quicker than installing a metal-based solution; thus, depending on local labor costs the savings potential is significant – up to 70%.

With textile-based air dispersion technology, the air is distributed evenly across the room at low velocity, thus avoiding drafts, dead zones and minimizing noise (<30NC) for higher comfort. With permeable fabrics, no condensation is formed on or inside the ducts, even if the inlet temperature is below the dew point. This prevents bacterial growth and mold for a more hygienic indoor environment. The bespoke solutions ensure better dispersion patterns and higher efficiency with lower pressure drops. Contrary to metal ducting, fabric ducts only require simple tools, such as a screwdriver, to install, which entails significant cost savings. Those are the four primary technological difference between fabric and metal air dispersion solutions.

www.fabricair.com

Construction News

05/09/2018

Differences Between Metal And Fabric Air Dispersion Technology

02/07/2025

Hydrogen sulfide (H₂S) is one of the most dangerous gases found in industrial environments.

Colourless, highly toxic, and often referred to as the "silent killer", it's particularly hazardous because it can quickly deaden the sense of smell, giving workers a false sense of security.

Even a

01/07/2025

Construction firm GRAHAM is making strong progress on the University of Manchester's flagship Fallowfield Campus redevelopment, working as part of the Viridis Consortium alongside partners Equitix and Derwent FM.

Following the demolition of the iconic Owens Park Tower, the project has now entered i

01/07/2025

Kirklees Council has announced that the West Yorkshire Archive Service (WYAS) will be moving into a new, purpose-built home within Huddersfield's flagship library hub, part of the Our Cultural Heart regeneration scheme.

The move marks a major milestone in the preservation and accessibility of the b

01/07/2025

Dalkia UK has officially assumed responsibility for the facilities management services at eight nuclear power stations operated by EDF Nuclear Operations.

The newly secured contract includes a wide range of essential services, including mechanical and electrical maintenance, building and grounds up

01/07/2025

Ofgem has provisionally approved a landmark £24 billion investment package to upgrade Britain's energy infrastructure, strengthen energy security, and accelerate the transition to clean power.

The initial funding, announced on July 1, is part of a wider £80 billion programme that represents the mo

01/07/2025

Engineering specialist MARCH has been appointed to United Utilities' Monitoring and Control Systems Integration framework, further strengthening its role in supporting vital water infrastructure projects across the North West.

The framework, which will initially run for five years with the potentia

01/07/2025

THE GUARDTECH GROUP are gearing up for a golden second half of year with THREE awards showpieces on the calendar.

First up, the cleanroom construction experts are finalists for the Large Business of the Year gong at the prestigious Suffolk Business Awards.

That event takes place on Thursday 10 Jul

01/07/2025

Leeds College of Building (LCB) has launched a refreshed brand identity and a new website as it celebrates 65 years of delivering specialist education and training in the construction industry.

The rebrand follows an 18-month collaboration with branding agency Born Communication, aiming to better r

01/07/2025

Three major projects delivered by Farrans have been named among the UK and Ireland’s best in the shortlist for the 2025 British Construction and Infrastructure Awards.

The Gull Wing Bridge in Suffolk, constructed by Farrans on behalf of Suffolk County Council, has been shortlisted in the Best Trans

01/07/2025

Persimmon Homes Wessex and Selwood Housing have formalised a new agreement to deliver additional affordable homes at the Backbridge Farm development in Malmesbury.

The two organisations have exchanged contracts on six high-quality homes, which Persimmon will complete and hand over to Selwood Housin

UK

UK Ireland

Ireland Scotland

Scotland London

London