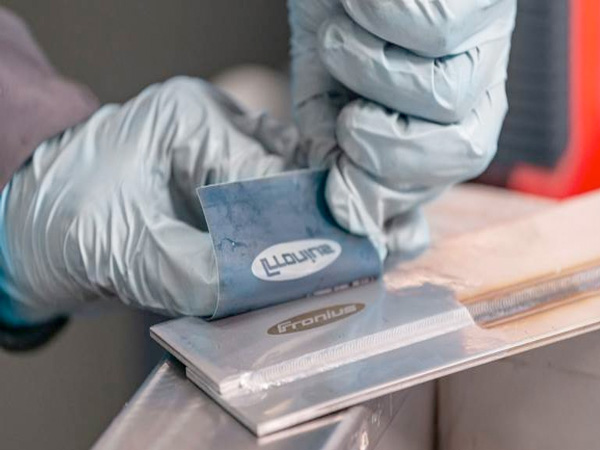

The new generation of the Fronius MagicCleaner – the advanced electro-chemical cleaner for the perfect finish on stainless steel TIG welds and surfaces – is now available in two variants.

In addition to meeting the highest standards of aesthetics and hygiene, Fronius has packed even more into the robust shell: TIG welds can now be polished to a shine and workpieces can be marked with logos or serial numbers.

From interfering with a clean visual appearance in architecture, commercial kitchens or stainless steel swimming pools to the food and pharmaceutical industry, strong temper colours range from being a mere visual distraction to a quality defect to be avoided at all costs. They indicate a chromium oxide protective layer that is not intact and which can be a starting point for corrosion or deposits.

Cleaning and passivation restore this protective layer over the weld and on stainless steel surfaces. With the MagicCleaner, these can even be carried out at the same time in one simple and time-saving step. At just 4.5 kilograms, the lightweight MagicCleaner 150 (15 A output) is the perfect portable companion for construction sites. Its big brother, the MagicCleaner 300, is ideal for more intensive applications and for cleaning longer TIG welds. Delivering up to 30 A of performance, the MagicCleaner 300 weighs 14 kilograms and has a 1.8 l cleaning fluid tank as well as a patented compressed air blower. Both devices can be operated intuitively and supply the cleaning pad with electrolyte, thus eliminating the cumbersome process of having to immerse it in a separate container full of liquid.

Precise and economical consumption

With the MagicCleaner, the electrolyte is precisely dosed and conveyed specifically to where it is needed. The pads and brushes included in the scope of supply even penetrate into corners and gaps, ensuring optimum cleaning with minimal use of materials. Electro-chemical cleaning is also much more resource-friendly than conventional pickling in chemical baths and does not attack the material, as is the case with sandblasting, for example. Naturally Fronius also uses innovative inverter technology for its weld-cleaning solutions, which makes the devices lightweight and particularly energy-efficient.

Three functions in one device: cleaning, polishing and marking

On highly polished materials, the weld seams should not only be pure, but downright radiant. Achieving this could not be easier thanks to the "electro-chemical polishing" function. Direct (DC) current is used to brighten the seams and make them shine in no time. But the MagicCleaner can do even more: company logos, item or serial numbers, and barcodes can be applied to stainless steel in black or white print. All that is needed is a suitably designed film and a special electrolyte solution. This is a good and cost-saving alternative to embossing, printing or gluing.

www.fronius.com

Construction News

24/02/2022

Clean Stainless Steel TIG Welds And Surfaces To Protection

22/05/2025

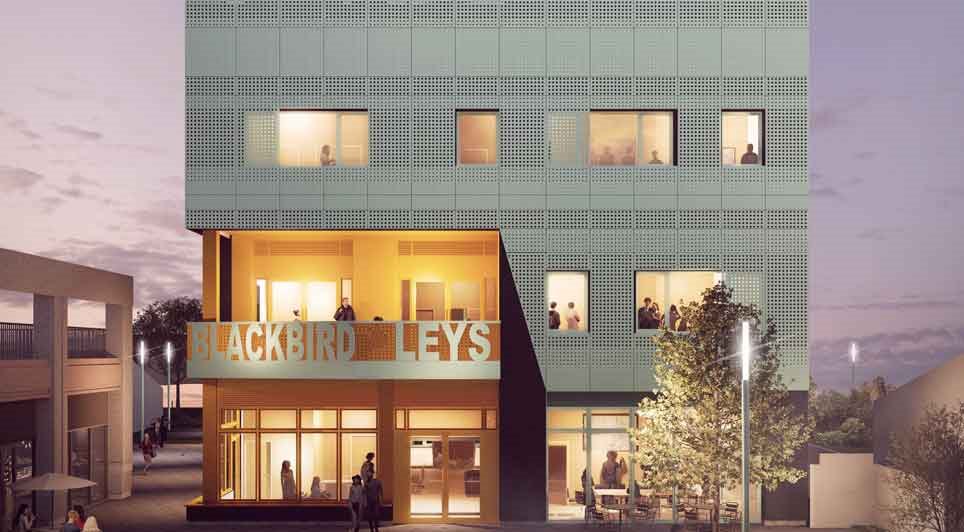

Oxford City Council has approved plans for a new, modern community centre in the heart of Blackbird Leys.

The council's planning committee gave the go-ahead on Tuesday 20 May, paving the way for construction to begin later this year.

The new centre is part of a broader redevelopment of the Distric

22/05/2025

Leading construction and facilities management company GRAHAM has officially commenced a new repairs and maintenance contract with Sandwell Property Care, part of the Council's Corporate Landlord team.

The contract covers the borough's extensive portfolio of non-housing properties, and will see GRA

22/05/2025

A significant milestone has been reached at Royal Bolton Hospital, as Bolton NHS Foundation Trust officially broke ground on the £38 million redevelopment of its Maternity and Women’s Health Unit.

The work is being carried out in partnership with Robertson Construction North West and marks the sta

22/05/2025

Galliford Try's Environment business has been honoured with a prestigious Silver Green World Award in recognition of its outstanding environmental efforts at the Tophill Low Water Treatment Works (WTW).

The project was selected from more than 1,200 entries worldwide, highlighting the global signifi

22/05/2025

A major new cement import facility planned for the North West of England is set to bolster growth in the UK construction sector while advancing the industry's efforts to reduce carbon emissions.

The deep-water terminal, to be built at the former P&O site at Gladstone Dock in Liverpool, is the resul

22/05/2025

A major new drainage initiative is under way across Oxfordshire, with work now started to clean and empty every highway gully in the county annually.

The £2.6 million programme, which began last month in Wheatley, will see nearly 145,000 highway drains, gullies, manholes, and catchpits cleaned by t

22/05/2025

Housing association Gentoo has announced a landmark investment programme aimed at improving more than 4,000 homes across Sunderland during 2025/26, in one of the city's largest ever housing improvement initiatives.

The multi-million-pound scheme will deliver a wide range of upgrades to thousands of

22/05/2025

Bilfinger UK has secured a key contract with National Gas to help maintain the flow of gas across the National Transmission System (NTS), a move that will create up to 100 jobs and support vital national infrastructure.

As Principal Designer and Principal Contractor, Bilfinger will lead a multi-dis

22/05/2025

A new strategic partnership has been formed between Network Rail Property, Places for London, and the London Borough of Lambeth to drive forward a major regeneration of London Waterloo Station and the surrounding South Bank neighbourhood.

The collaboration follows the publication of the Waterloo St

22/05/2025

Wythenshawe Park has seen a series of improvements aimed at making it more accessible and enjoyable for all visitors, as part of Manchester City Council's £157,000 Clean, Green, Safer Manchester Investment.

The funding supports a wider initiative to enhance green spaces across the city and has been

UK

UK Ireland

Ireland Scotland

Scotland London

London