The Keyfix Non-Combustible Cavity Tray System has proven integral to the construction of a new high-rise residential development in South West London, by improving installation efficiency and quality on site, and exceeding building regulations.

Conveniently located in the heart of Wandsworth, between Clapham Junction and Battersea, new residential developments have been built on Shuttleworth Road. The homes have been constructed under Wandsworth London Borough Council’s 'Housing for All' regeneration scheme, which provides 62 social rented homes, and nine shared ownership apartments, varying from one to three bedrooms. The new-build homes have been made to adaptable standards of accessibility, with eight homes being fully wheelchair accessible. All the homes have been prioritised for those who live and work in the borough, with 60% of the homes being affordable.

Working alongside contractor Wates and ECD Architects on the project, Keyfix supplied 1,300 metres of Non-Combustible Cavity Trays (NCCT), 413 corner units and 3,351 Weeps to protect the new-build project and increase its longevity.

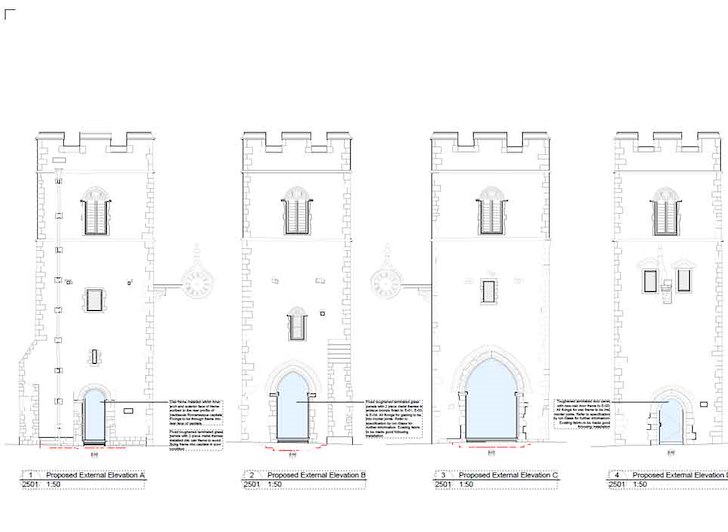

The project presented a significant challenge for the client, given that the inset dog-leg window detail resulted in unconventional specifications. Keyfix overcame the challenge by visiting the site in advance of the product’s arrival, allowing the team to pre-empt any issues. Keyfix provided a complete technical review including a full mark-up plan, including elevations and sections. The team was then able to adapt the non-combustible cavity trays to the layout of the building. Additionally, the pre-formed corner units on this project were at obtuse angles as opposed to the standard 90-degree angle. The technical provisions made by Keyfix, prior to the product delivery, allowed for the rapid installation of pre-formed corner units.

Tom Hooper-Smith, Construction Manager at Wates, commented: "We were greatly impressed by Keyfix’s performance on this project. Keyfix carried out a full mark-up and had seen issues onsite before the product was delivered, so they were able to modify the NCCT system to suit the building layout. We were especially impressed with Keyfix’s innovation in modifying the trays to accommodate the inset dog-leg window detail on this project."

The Keyfix NCCT was specified by the client, as they required an A1 fire rated product on this high-rise project. The Keyfix NCCT was an obvious choice as it is made to exceed the minimum standards set out in ADB (Approved Document B), and will never contribute to fire loading in the building.

]The NCCT was also selected due to the innovative, self-supporting design of the tray, and the ease of installation. The Keyfix NCCT allows for a fast and efficient installation, as it does not need to be attached to the inner concrete structure. In contrast to other cavity tray systems, the Keyfix NCCT requires no additional fixings, sealants or onsite fabrication by the brickwork contractor. This is very beneficial on site, as it significantly reduces installation time, when compared to traditional DPC.

This pioneering cavity tray system is installed in the outer leaf with no connection to the inner skin, therefore, it does not create a thermal bridge, improving thermal performance and allowing the homeowner to save on energy costs. This also benefits the homeowner by safeguarding the building against issues associated with differential movement.

UK

UK Ireland

Ireland Scotland

Scotland London

London