HS2 Ltd has announced the start of construction on the railway's first and longest viaduct with the launch of an enormous 700 tonne bridge-building machine at an event attended by the HS2 Minister, Andrew Stephenson MP, just outside London.

Stretching for more than two miles (3.4km) across a series of lakes and waterways between Hillingdon and the M25, the Colne Valley Viaduct will also be the longest railway bridge in the UK.

The start of construction is the latest major milestone in the delivery of the HS2 project, which is designed to improve rail links between London, Birmingham and North, help level-up the economy and provide a low carbon alternative to car and air travel.

Mr Stephenson said: "HS2 began construction on what’s set to be Britain’s longest railway viaduct, a landmark moment for HS2 and a feat of British engineering, taking the HS2 line from London, and into Hertfordshire and Buckinghamshire.

"Infrastructure is the backbone of HS2 and this viaduct will be integral to delivering faster journeys and an increased capacity rail network."

Known as a 'launching girder', the 160m long bridge-building machine is the only one of its kind in the UK and will be used to lift the giant concrete deck segments that form the viaduct’s arches into position. Once each section is complete, the machine will inch itself forward into position to build the next stage.

A total of one thousand deck segments will be needed, with each one weighing up to 140 tonnes. To allow for the gentle curves of the viaduct as it crosses the valley, all the segments are slightly different shapes and made on site at a purpose-built temporary factory close to the north abutment.

The huge viaduct project is being led by HS2's main works contractor Align JV – a team made up of Bouygues Travaux Publics, Sir Robert McAlpine and VolkerFitzpatrick.

Originally built in 2004, the launching girder was first used during the construction of the Hong Kong East Tsing Yi Viaduct. Specially designed to handle complex viaduct construction, the machine is named ‘Dominique’ in memory of Bouygues engineer Dominique Droniou who played a leading role in its design and development.

56 piers each weighing around 370 tonnes are being constructed along the Colne Valley ahead of the girder, with the girder moving from one pier to the next, installing the deck segments as it goes. One segment is put in place each side of the central pier, using a cantilever approach to balance the structure, as two half-arches either side of each pier are constructed simultaneously. Steel tensioning cables will be threaded through the segments to strengthen the bridge.

Every segment will be a slightly different shape depending on where it fits into the viaduct and the modular approach was chosen to ensure quality, safety and efficiency.

The viaduct pre-cast factory where the segments are made at the peak of construction will cast around 12 segments every week using a ‘match-casting’ technique. This approach - where each segment is poured against the previous one - will ensure the whole deck fits perfectly when assembled on the piers. The mammoth 100m long viaduct precast factory, which is visible from the M25, has an internal volume of 105,000 cubic metres – making it larger than the Royal Albert Hall.

Once construction is complete, the factory and surrounding buildings will be removed and the whole area between the viaduct and the Chiltern tunnel will be transformed into an area of chalk grassland and woodland as part of HS2’s 'green corridor' project.

The design of the Colne Valley Viaduct was inspired by the flight of a stone skipping across the water, with a series of elegant spans, some up to 80m long, carrying the railway around 10m above the surface of the lakes, River Colne and Grand Union Canal.

Set low into the landscape, wider spans will carry the viaduct crosses the lakes, with narrower spans for the approaches. This design was chosen to enable views across the landscape, minimise the viaduct’s footprint on the lakes and help complement views across the natural surroundings.

In another visible sign of progress on the project, the team have also completed the construction of three of four jetties across the lakes to get equipment into position to support the construction and help take construction vehicles off local roads. Where the viaduct crosses the lakes, the piles are being bored directly into the lakebed, using a cofferdam to hold back the water while the pier is constructed.

Construction News

01/06/2022

Construction Begins On UK's Longest Railway Bridge

08/07/2025

Morgan Sindall Construction has announced the successful completion of the main building phase for the King Henry VIII 3-19 School redevelopment in Abergavenny, a transformative £62.5 million project delivered via the SEWSCAP framework. A celebration was held to mark the handover of the new building

08/07/2025

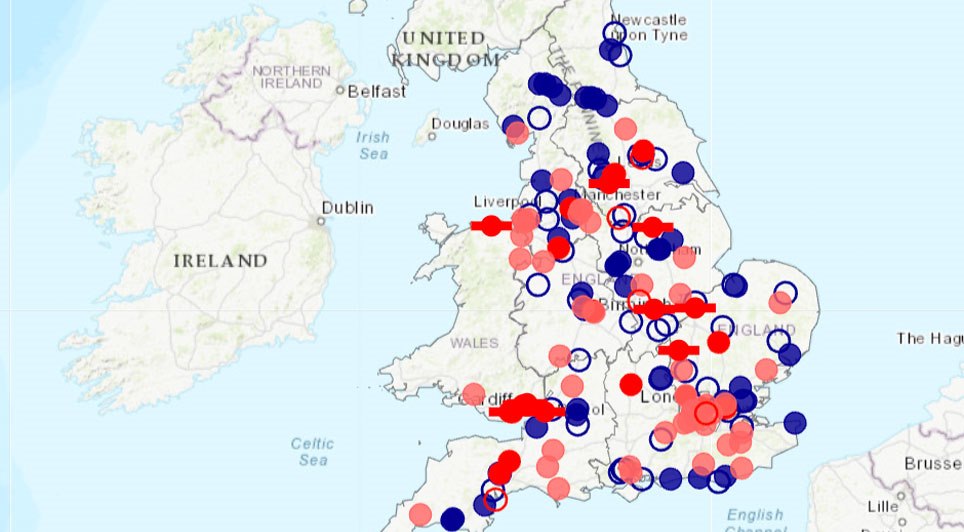

The government has today confirmed funding for over 50 road and rail infrastructure upgrades. These projects, which include long-awaited schemes such as the A66 Northern Trans-Pennine route and the Portishead to Bristol city centre rail line, are anticipated to provide a substantial boost to the con

08/07/2025

The shortlist for the 2025 Top 100 Most Influential Women in Construction Awards has been unveiled by the Construction Industry Training Board (CITB).

Now in its fourth year, the initiative continues to champion the significant contributions of women across the industry, aiming to make female role

08/07/2025

Watts Group, a prominent property and construction consultancy, has today published the 30th edition of its widely respected 'Watts Pocket Handbook', marking nearly a decade since its previous release.

Recognised as a vital resource for professionals across the built environment, this latest editi

08/07/2025

A team of staff from Leeds College of Building (LCB) recently made their debut at 'The Big Construction Diversity Challenge 2025'. The annual event, held on Friday, 27 June 2025, at Newark Showground, serves as a key platform to promote the crucial importance of equality, diversity, and inclusion (E

08/07/2025

Dan McGrail has been officially appointed as the permanent Chief Executive Officer of Great British Energy, the UK's publicly-owned clean power company.

His appointment aims to accelerate the government's Plan for Change, with a core mission to establish the UK as a clean energy superpower. Mr McG

08/07/2025

Understanding Custom Rubber Diaphragms

Custom rubber diaphragms are essential components in various industrial applications, playing a crucial role in enhancing performance and efficiency. As a manufacturer specialising in these versatile components, we've witnessed firsthand the impact th

08/07/2025

Modular tiles are among the most popular option for flooring at the minute. These bring character and sophistication through their layout. Most frequently these are made from porcelain which makes them multifunctional and highly durable. Modular tiles are suitable for old and new properties and are

07/07/2025

Travelodge has officially broken ground on a new 100-room hotel in Loughton, marking the latest addition to the UK's first budget hotel brand's expanding portfolio.

The company, which operates more than 610 hotels across the UK, Ireland and Spain, is aiming to meet growing demand for affordable ac

07/07/2025

Oldham Council has officially unveiled Snipe Gardens, a newly created green space and pedestrian gateway designed to provide a welcoming entrance into the town centre.

Situated on the site of the former Snipe Inn pub, the new landscaped area links Oldham bus station with Henshaw Street. As one of t

UK

UK Ireland

Ireland Scotland

Scotland London

London