Fronius is adding to its range of smart, high-end TPS/i TWIN tandem welding systems. Synchronized welding with two individually controllable arcs has never been so easy as with the new TPS/i TWIN systems and the PMC TWIN and CMT TWIN welding processes. Both systems boast stable penetration and help save time thanks to their high speed and impressive deposition rate.

When it comes to high performance tandem welding, the main challenge is successfully controlling both arcs. Achieving this allows operators in the container, vehicle, and wagon construction industries to easily perform multi-layered or long welds in order to produce top-quality large-scale components. The TPS/i TWIN Push system, which is already well established on the market, is now joined by TWIN Push-Pull systems including the CMT TWIN process, which is well equipped to deal with such challenges. From now on, it will be possible to use tandem welding systems to join aluminum as well as steel.

• Two Versatile Powerhouses

The TPS/i TWIN Push-Pull solution is designed for use in motor vehicle and railway vehicle construction, and is used to weld aluminum profiles or pressure containers using the PMC (Pulse Multi Control) process. In addition to the PMC process, the new TPS/i CMT TWIN system also uses the CMT (Cold Metal Transfer) process, thereby also enabling welding of aluminum, nickel-base alloys, and high-strength steels. The controlled heat input provided by the Cold Metal Transfer process is also particularly well suited for thin sheet applications. Penetration and weld profile can be further optimized if each TWIN arc is set to a different performance level.

• High Speed and 25kg Deposition Rate

In practice, the benefits of tandem welding compared to single wire welding are particularly apparent in cases where a perfect result needs to be produced at high speed. With a deposition rate of up to 25 kilograms per hour and a speed of up to 4 meters per minute, the Fronius TPS/i TWIN systems are quite the workhorses. This is made possible thanks to a wire speed performance of around 30 meters per minute for each processing line. Despite this speed, a flawless finish is achieved with reliable penetration quality and no weld-seam porosity. This reduces both the number of layers and the production time.

• Exceptional Weld Quality – Achievable at Any Time

The integrated self-regulating TWIN process ensures optimal results and high efficiency, with only the essential settings needing to be adjusted. In the background, the system independently controls the welding parameters and variables to ensure the arcs are always precise. In order to ensure completely stable welding, a high level of process reliability is required, and this is guaranteed by the combination of PMC and CMT. Innovative solutions for optimal wire feeding such as the TWIN Drive or the wire buffer component ensure a steady supply of wire, thereby increasing the reliability of the welding process and taking process stability to another level. This cuts reworking and production errors to a minimum, thus saving time and resources.

• Rapid and Precise Thanks to Smart Assistance Systems

The Fronius TWIN series offers a range of different functions and robot assistance systems that help welders to automate the production process as efficiently as possible. For example, SFI (spatter-free ignition) prevents spatter during ignition and the innovative chipping hammer removes previously formed slag by way of reversing the wire movement to ensure a clean start to the weld. SeamTracking automatically compensates for deviations, and TouchSense equips the robot with a positioning sensor that it can then use to compensate for clamping and component tolerances. WireSense measures these tolerances and transmits them directly to the robot. All this reduces welding errors, reworking time, and even discards, which directly contributes to increasing efficiency in high performance welding.

For further information, please visit our website.

Construction News

05/05/2022

New Additions To Fronius TPS/i Twin Tandem Welding Series

08/07/2025

Morgan Sindall Construction has announced the successful completion of the main building phase for the King Henry VIII 3-19 School redevelopment in Abergavenny, a transformative £62.5 million project delivered via the SEWSCAP framework. A celebration was held to mark the handover of the new building

08/07/2025

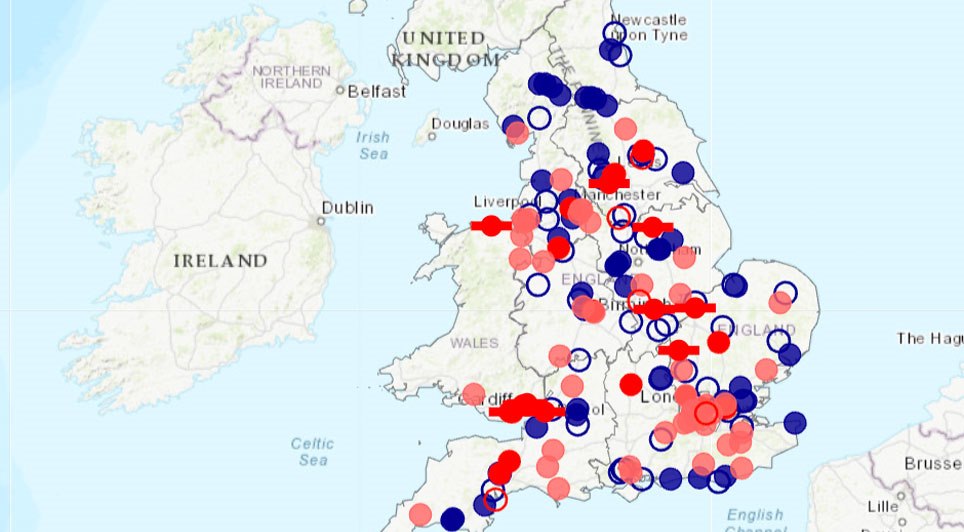

The government has today confirmed funding for over 50 road and rail infrastructure upgrades. These projects, which include long-awaited schemes such as the A66 Northern Trans-Pennine route and the Portishead to Bristol city centre rail line, are anticipated to provide a substantial boost to the con

08/07/2025

The shortlist for the 2025 Top 100 Most Influential Women in Construction Awards has been unveiled by the Construction Industry Training Board (CITB).

Now in its fourth year, the initiative continues to champion the significant contributions of women across the industry, aiming to make female role

08/07/2025

Watts Group, a prominent property and construction consultancy, has today published the 30th edition of its widely respected 'Watts Pocket Handbook', marking nearly a decade since its previous release.

Recognised as a vital resource for professionals across the built environment, this latest editi

08/07/2025

A team of staff from Leeds College of Building (LCB) recently made their debut at 'The Big Construction Diversity Challenge 2025'. The annual event, held on Friday, 27 June 2025, at Newark Showground, serves as a key platform to promote the crucial importance of equality, diversity, and inclusion (E

08/07/2025

Dan McGrail has been officially appointed as the permanent Chief Executive Officer of Great British Energy, the UK's publicly-owned clean power company.

His appointment aims to accelerate the government's Plan for Change, with a core mission to establish the UK as a clean energy superpower. Mr McG

08/07/2025

Understanding Custom Rubber Diaphragms

Custom rubber diaphragms are essential components in various industrial applications, playing a crucial role in enhancing performance and efficiency. As a manufacturer specialising in these versatile components, we've witnessed firsthand the impact th

08/07/2025

Modular tiles are among the most popular option for flooring at the minute. These bring character and sophistication through their layout. Most frequently these are made from porcelain which makes them multifunctional and highly durable. Modular tiles are suitable for old and new properties and are

07/07/2025

Travelodge has officially broken ground on a new 100-room hotel in Loughton, marking the latest addition to the UK's first budget hotel brand's expanding portfolio.

The company, which operates more than 610 hotels across the UK, Ireland and Spain, is aiming to meet growing demand for affordable ac

07/07/2025

Oldham Council has officially unveiled Snipe Gardens, a newly created green space and pedestrian gateway designed to provide a welcoming entrance into the town centre.

Situated on the site of the former Snipe Inn pub, the new landscaped area links Oldham bus station with Henshaw Street. As one of t

UK

UK Ireland

Ireland Scotland

Scotland London

London