Address

Units A/B, Breener Ind. Estate

Station Drive

Station Drive

Dudley

West Midlands

DY5 3JZ

England, UK

About Arc Alloys Ltd

We offer a genuine 24/7 technical advice service utilising 30 years of industry experience in welding and fabrication, consumable supply, welding process and machining.

We empathise with our customers and their needs and know that issues do arise outside of normal working hours. It is reassuring, and can be invaluable, knowing that there is always someone available at the end of the telephone to support you with any queries you may have.

We focus on building strong long-term relationships with our clients, as we consider sound client relationships the most important contributor to our success. We cement these relationships by delivering outstanding customer service promptly and of a consistently high quality.

Welding and Fabrication Services

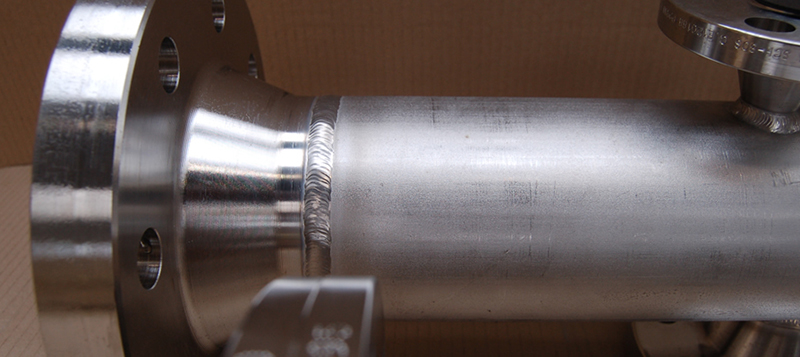

Welding and fabrication has been at the core of Arc Alloys business since 1998. We now have an established reputation for manufacturing products, which operate in severe environments, to the highest levels of quality and stringent levels of dimensional accuracy. All our welding procedures are certified by independent third party authorities to international standards including ASME IX and ISO 15614.

Materials

Our qualified procedures cover material grades which include the following:

Welding Processes

We continually monitor the advancement in welding technology and techniques, currently employing the following methods:

Products we manufacture include:

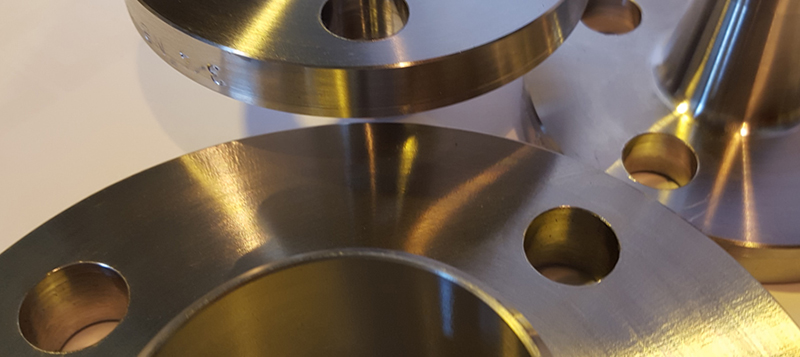

Arc Alloys was established in 1988, supplying a wide range of welding consumables to the repairs, maintenance and special metal sectors. Ten years later, in 1998, we launched a manufacturing facility to help us meet customer requirements and supply ancillary products and welded pressure vessels to clients in the petrochemical, oil and gas industries. As our fabrication services have expanded over the years, we can now supply pipes, flanges and fittings in most Duplex, Super Duplex, stainless and Nickel Alloy grades.

Welding and fabrication has been at the heart of Arc Alloys since 1998. In that time, we have gained a reputation for manufacturing quality products that are made to the most meticulous levels of accuracy and capable of withstanding the severest external conditions.

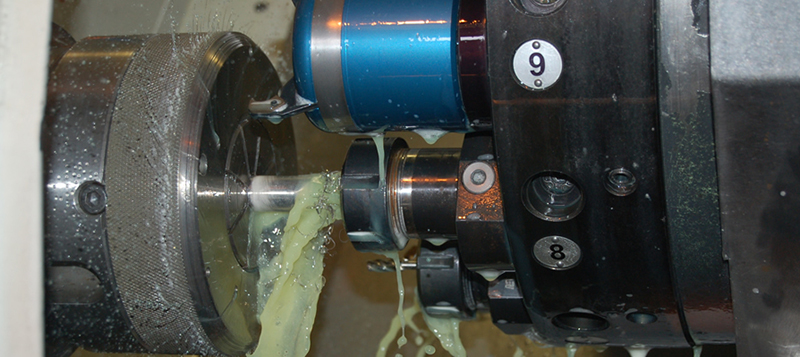

Metal fabrication is an industrial process wherein structural steel or sheet metal is cut, bent, shaped and reassembled into metallic structures or objects. We have dedicated machines for every mechanical process, including lathes, shears, guillotines, sheet metal machines, folders and benders, rolls and punches.

What materials can be fabricated?

We work with a wide range of metals and materials, including:

We have dedicated machine shop capabilities which when combined with close working relationships with forgemasters, butt weld fitting and flange stockists allows us to offer full supply of bespoke flanges and fittings, either as a sub contract stand-alone customer requirement or as an integral part of a full supply assembly.

We work comfortably with low alloy through to exotic alloys and enjoy the support of highly skilled and motivated staff. We are committed to continuous investment so that we are able to deliver comprehensive and cost effective machining services and solutions.

We empathise with our customers and their needs and know that issues do arise outside of normal working hours. It is reassuring, and can be invaluable, knowing that there is always someone available at the end of the telephone to support you with any queries you may have.

We focus on building strong long-term relationships with our clients, as we consider sound client relationships the most important contributor to our success. We cement these relationships by delivering outstanding customer service promptly and of a consistently high quality.

Welding and Fabrication Services

Welding and fabrication has been at the core of Arc Alloys business since 1998. We now have an established reputation for manufacturing products, which operate in severe environments, to the highest levels of quality and stringent levels of dimensional accuracy. All our welding procedures are certified by independent third party authorities to international standards including ASME IX and ISO 15614.

Materials

Our qualified procedures cover material grades which include the following:

- Carbon Steels

- Carbon Steels with P.W.H.T.

- Low – Temperature Carbon Steel (A333 Grade 6)

- CrMo Steels (P11)

- 300 Series Stainless Steel (304, 316, 321,347)

- Duplex

- Super Duplex

- Inconel 625

- Hastelloy C276

- Carpenter 20

- Monel 60 (Alloy 400)

- Titanium

- Dissimilar Combinations

Welding Processes

We continually monitor the advancement in welding technology and techniques, currently employing the following methods:

- Gas Tungsten Arc Welding (GTAW)

- Shielded Metal Arc Welding (SMAW)

- Gas Metal Arc Welding – MIG, MAG (GMAW)

- Flux Cored Arc Welding (FCAW)

- Plasma Arc Welding (PAW)

- Brazing / Silver Brazing (TB)

Products we manufacture include:

- Pressure Vessels. Vessels in special alloys, or of specialised design requirements are manufactured for Onshore, Offshore and Nuclear applications.

- “Y-Type” and “T-Type” Strainers. Used in filtration and process industries

- Inlet / Outlet Header Assemblies. Used in heat transfer

- Access Fittings. Produced in various alloys, including exotic, used in process piping for chemical injection / corrosion monitoring.

- Floats and Vibrating Forks – Magnetic and Vibrating Level Switches, used in all areas where fluid measurement and control is required.

Arc Alloys was established in 1988, supplying a wide range of welding consumables to the repairs, maintenance and special metal sectors. Ten years later, in 1998, we launched a manufacturing facility to help us meet customer requirements and supply ancillary products and welded pressure vessels to clients in the petrochemical, oil and gas industries. As our fabrication services have expanded over the years, we can now supply pipes, flanges and fittings in most Duplex, Super Duplex, stainless and Nickel Alloy grades.

- Welding Consumables

- Machining activities and capabilities

- Quality Assurance

- Materials

Welding and fabrication has been at the heart of Arc Alloys since 1998. In that time, we have gained a reputation for manufacturing quality products that are made to the most meticulous levels of accuracy and capable of withstanding the severest external conditions.

Metal fabrication is an industrial process wherein structural steel or sheet metal is cut, bent, shaped and reassembled into metallic structures or objects. We have dedicated machines for every mechanical process, including lathes, shears, guillotines, sheet metal machines, folders and benders, rolls and punches.

What materials can be fabricated?

We work with a wide range of metals and materials, including:

- Various types of plate metal

- Pre-formed and expanded metal

- Welding wire

- Fittings and castings

- Various types of carbon steel

- Stainless steel

- Various corrosion-resistant alloys

We have dedicated machine shop capabilities which when combined with close working relationships with forgemasters, butt weld fitting and flange stockists allows us to offer full supply of bespoke flanges and fittings, either as a sub contract stand-alone customer requirement or as an integral part of a full supply assembly.

We work comfortably with low alloy through to exotic alloys and enjoy the support of highly skilled and motivated staff. We are committed to continuous investment so that we are able to deliver comprehensive and cost effective machining services and solutions.

UK

UK Ireland

Ireland Scotland

Scotland London

London