Telephone

Click to view

Fax

02085 002 554

Contact

Gary Middleton

Email

Address

Unit 8D, The Cromwell Centre

Roebuck Road

Roebuck Road

Ilford

London

IG6 3UG

About G Middleton Engineering

A small engineering company with a wide range of metalworking capabilities

We started out making parts and accessories for motorcycles, notably aluminium petrol caps, which used our machining (turning and milling), pressing and polishing processes. Over the years we have added sheet metalwork, welding and fabrication equipment and now work with Mild Steel, Stainless Steel, Brass and Plastics to produce a wide range of products and parts from tiny screws to large sliding gates.

We started out making parts and accessories for motorcycles, notably aluminium petrol caps, which used our machining (turning and milling), pressing and polishing processes. Over the years we have added sheet metalwork, welding and fabrication equipment and now work with Mild Steel, Stainless Steel, Brass and Plastics to produce a wide range of products and parts from tiny screws to large sliding gates.

Industries/markets served include:

- Automotive/Motorcycle: Apart from the petrol caps mentioned above, we have produced various parts, often bespoke/one-off, such as luggage racks for motorcycles, brake caliper mounting plates for both cars and bikes, intake manifolds etc. Even a race car tubular spaceframe chassis. We also do repairs and refurbishments - cracks in alloy wheels, engine or gearbox cases, repaired by welding. Motorcycle forks, frames, engine cases, car wheels, engine bay parts polished to a show finish.

- Architectural Metalwork/Construction: Door and window hardware, such as Door “Shoes”, Pivot parts, brackets and handles. Balustrading/handrails in both Mild Steel and Stainless Steel. Complete staircases, gates & railings. Brackets & supporting frames, such as sometimes required for bi-fold door installations (especially in aluminium). Even lightweight roof truss frames (but NOT structural steelwork).

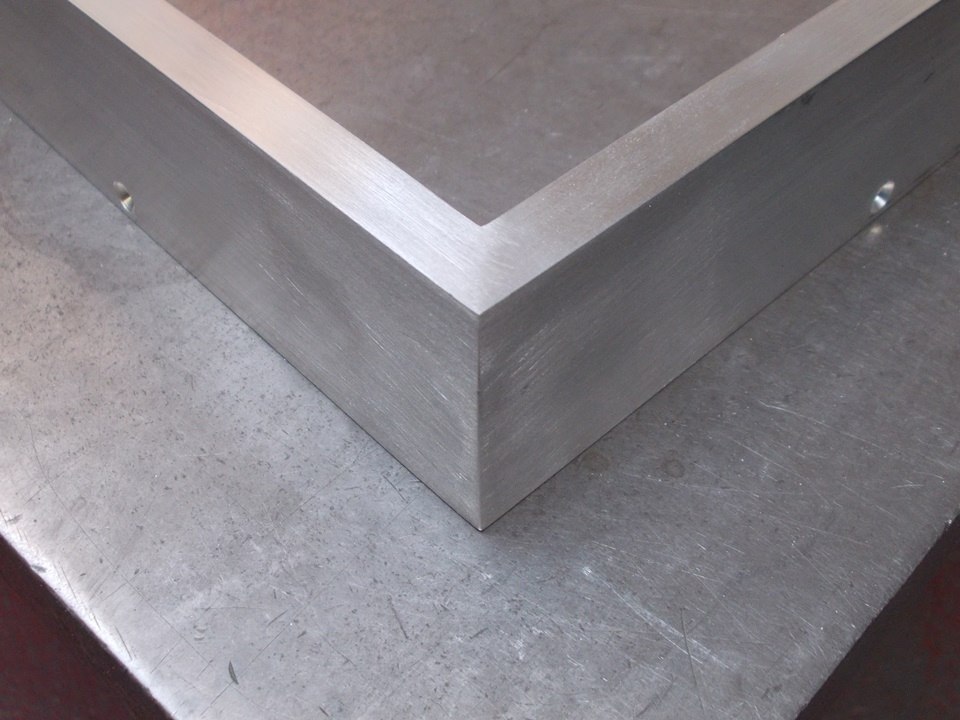

- Household/interiors/furniture: Bespoke shelving units, lighting parts, aluminium picture frames, legs and frames for tables and chairs.

- Industrial/Power: General machining, welding of various parts, repair or re-manufacture of old or obsolete parts, again working with Mild Steel, Stainless Steel and Aluminium.

- Plant/Equipment: Machining: CNC turning centre, manual lathes up to 7 1/2” centre height x 50” b.c., Turret, Vertical & Horizontal milling machines (one with slotting attachment), bench and pillar drills, Pantograph Engraver.

- Cutting, grinding, finishing: Cut-off saws (high speed for aluminium, low speed for steel), vertical band-saw, Surface grinder, vertical and horizontal Linishers, Flat Lapping machine, Polishing Spindle, hand grinders, angle polisher, pipe polisher, sanders. Small bead blast cabinet.

- Sheet metal/presswork: 3 ft. Treadle Guillotine, 1250mm x 2mm folder, 4 ft. x 3” manual bending rolls, various Fly-presses.

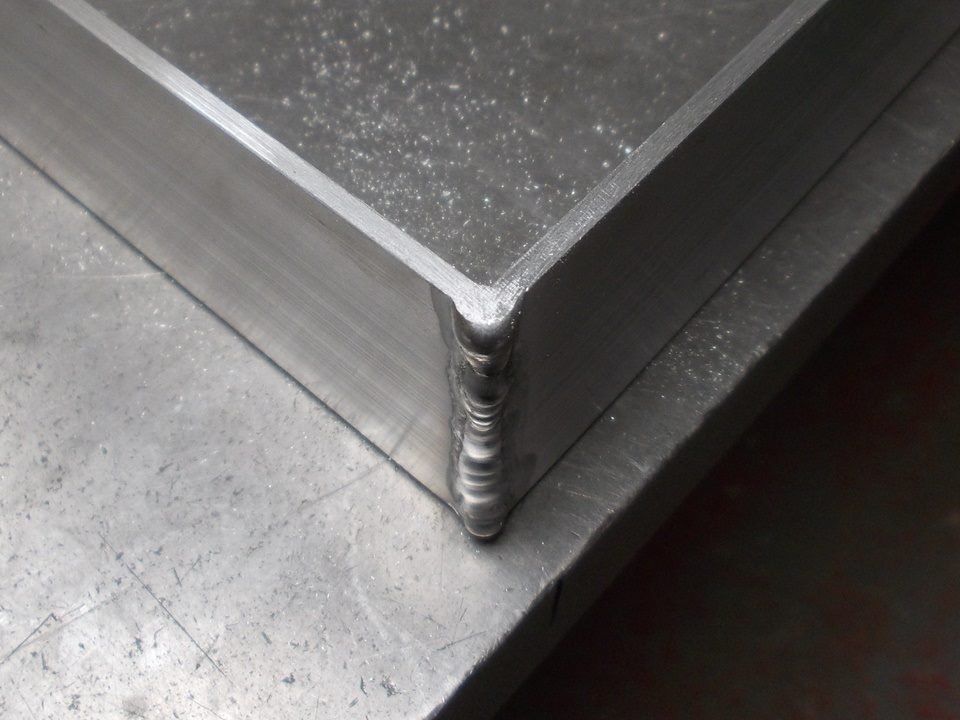

- Welding: 350 Amp AC/DC TIG welder (for Mild and Stainless steels, Aluminium, TIG Brazing), 210 Amp Standard MIG welder (for Mild Steel), 450 Amp Transpulse Synergic MIG welder (for Mild & Stainless Steels, Aluminium, MIG Brazing), Spot Welding machines.

We also do refurbishment/re-polishing of existing hardware, such as brass floor plates, handles, letter plates, etc.

UK

UK Ireland

Ireland Scotland

Scotland London

London