Time and date

CONSTRUCTION DIRECTORY

Angstrom Technology Contact Details

Address

Riverside House

Forge Lane, Halton

Forge Lane, Halton

Lancaster

LA2 6RH

England UK

About Angstrom Technology

Angstrom Technology deliver turnkey and modular cleanroom design and build projects. With our validation and maintenance, cleanroom training, and consumables and equipment services, we provide contamination control way beyond the commissioning of your cleanroom.

Welcome to Angstrom Technology UK. We are proud to be part of the Angstrom Technology Group providing global cleanroom and controlled environment solutions.

In 2022, Angstrom Inc. invested in Connect 2 Cleanrooms Limited and Specific Environments Limited, bringing together two of the UK’s leading cleanroom brands into one integrated UK company. Now, with an enviable team of cleanroom design and build experts, validation and commissioning professionals, CPD-accredited training and the consumable and equipment division, Cleanroomshop, Angstrom Technology UK is truly an end-to-end lifecycle solution provider.

Committed to delivering high-quality cleanroom products and services, our team of experts has extensive industry experience ensuring our solutions meet the stringent requirements of sectors such as pharmaceuticals, biotechnology, healthcare, electronics, and more.

With a UK network of offices, in High Wycombe, Lancaster and York, we are ideally placed to support customers across the country. We also have a dedicated training facility and showroom at our office in Lancaster.

By making your process requirements our priority, we build contamination control solutions that manage risk. As cleanroom specialists, we understand the complex and critical nature of meeting regulatory requirements and—most importantly—you can trust us to get you there.

Cleanroom Solutions

Developing the most appropriate cleanroom to transform your production is our passion. Our scalable and connected cleanrooms provide protection and regulatory compliance for our client’s critical processes.

Cleanroom Design & Build

Angstrom Technology offers a full range of cleanroom design & build services. From design only packages to full architectural fit-out services, we have specialist, in-house expertise to help you at every stage.

ISO & EU GMP Training

The biggest contamination risk in a cleanroom is people and products. Our CPD-certified ISO and EU-GMP cleanroom training courses educate delegates on protocols and contamination control.

Validation & Requalification

With a tailored cleanroom qualification testing schedule, Angstrom Technology will certify the class or grade of your cleanroom facilities and localised clean air devices.

Consumables & Furniture

Our consumables and equipment division, Cleanroomshop, supplies a varied portfolio of products from leading brands, along with supportive pricing and delivery mechanisms. All with the highest levels of service.

Regulatory Compliance Support

All cleanroom projects with a requirement for GMP will have oversight from our dedicated regulatory governance team. With over 30 years’ combined experience in GMP & pharmaceutical industries, this level of in-house expertise sets us apart rom other cleanroom companies.

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!

Gallery

|

Click to close

|

News

15/02/2024

Angstrom Technology provides full suite of cleanroom services for Plexus Corp.

Angstrom Technology provides full suite of cleanroom services for Plexus Corp.

Angstrom Technology was appointed to work alongside Plexus Corp, fulfilling their brief to design and build a new cleanroom facility for manufacturing components for their customer within the semiconductor industry.

The Client

Plexus is a global organisation that is contracted by its customers to design, manufacture and service their products. Employing over 25,000 people worldwide, Plexus operates in the industrial, healthcare, life sciences, aerospace and defence sectors and works with highly complex customers with many regulations to comply with.

At its Livingstone site in Scotland, Plexus is working to develop two cleanroom facilities; one permanent facility and one smaller, temporary facility to enable production to commence ahead of the completion of their larger, permanent facility.

The project

Plexus originally produced a User Requirement Specification (URS) for the project as part of the tender process and chose Angstrom Technology as their solution provider, due to the range of services we offer. Utilising our expertise in cleanroom design & build, cleanroom validation, cleanroom consumables and cleanroom training, Plexus were attracted to the prospect of a single provider to manage the entire process. As such, the Angstrom team worked collaboratively to refine their URS and bring their requirements to life.

Each feature of the cleanroom was carefully designed and critical to its success. It was decided that a temporary cleanroom would be utilised as a stopgap until their larger, permanent facility was completed.

The Cleanroom

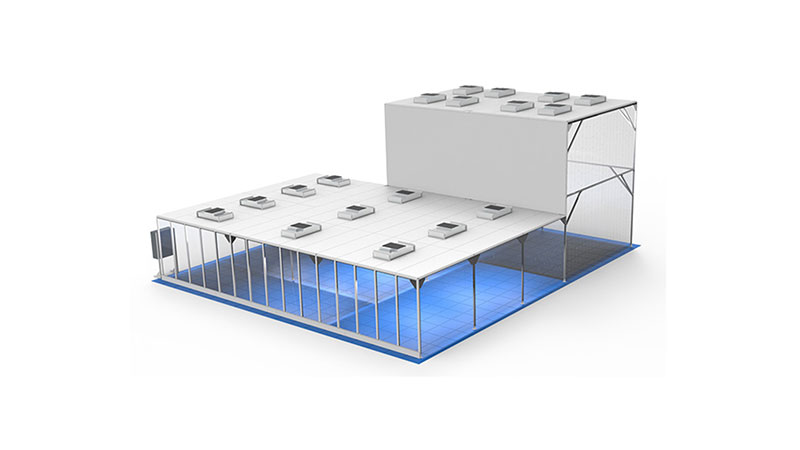

Angstrom Technology was appointed to design and build a 30m x 15m cleanroom facility, whilst at the same time producing a smaller, temporary, hybrid cleanroom.

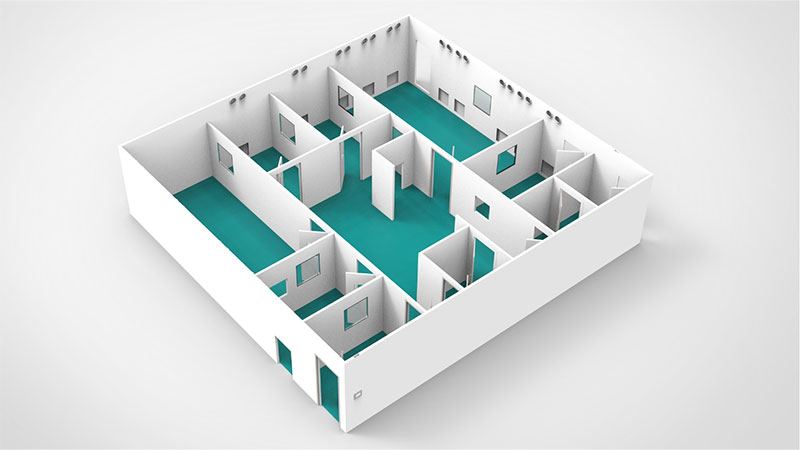

Designed in Lancaster and built on-site in Scotland, the temporary cleanroom is a 5m x 10m hybrid structure (meaning a combination of both hardwall and softwall panels) and features HEPA filtration, achieving ISO class 7. The brief also included a softwall curtain divide to create an area separate from the main room that is used as both a change area and a pre-cleanroom inspection area. This enables the team to clean and prepare components that haven’t been manufactured in a cleanroom before they enter the main cleanroom area to prevent cross-contamination.

The Consumables

Along with the cleanroom design and build project, it was clear that a carefully selected range of cleanroom furniture would be required to make it operational. The purpose of the cleanroom is to manufacture components designed for use within the semiconductor industry. Due to the sensitive nature of their processes, furniture with antistatic properties was key, and our team were able to advise on what would be best for their processes on this basis.

Angstrom Technology’s consumables and equipment division, Cleanroomshop, offers a varied portfolio of products from a wide range of global brands.

As part of an initial visit the client made to the Angstrom Technology Lancaster office, they were able to see our showroom, which is coincidentally a hybrid cleanroom and features elements of the design specification of the preliminary cleanroom. Cleanroomshop Key Account Manager (Furniture), Lois, was on hand to discuss the furniture options and develop a list of appropriate furniture for their cleanroom requirements.

Further to this, Lois conducted an on-site visit where the cleanroom was being constructed, to collaborate with the Plexus team and evaluate appropriate furniture options. The client opted for a range of electropolished steel furniture, consisting of benches, chairs and garment cupboards including shoe storage, shelving and more. Due to the unique nature of their processes, the client also chose a selection of antistatic tables and benches that were custom-made to their bespoke requirements.

The Training

Once the physical cleanroom and consumables had been agreed upon, a selection of the client’s team attended training at Angstrom Technology’s Lancaster office. The team completed our CPD-certified ISO Cleanroom Training Course, which helps attendees control the introduction, generation, and retention of particles in cleanrooms in line with ISO standards.

Upon completion of the training course, participants were awarded a certificate of attendance for their records. The feedback received from all participants was positive and as such, Plexus suggested they may extend cleanroom training to more of their operatives upon completion of the permanent cleanroom.

Customer Quote

“We originally appointed Angstrom Technology to this project because of the support and engagement we received from the word go. We felt the team went above and beyond in terms of design work, modifications and ISO classification, and the fact they could produce a hybrid cleanroom made them stand out to us.

We opted to utilise the full su

Angstrom Technology was appointed to work alongside Plexus Corp, fulfilling their brief to design and build a new cleanroom facility for manufacturing components for their customer within the semiconductor industry.

The Client

Plexus is a global organisation that is contracted by its customers to design, manufacture and service their products. Employing over 25,000 people worldwide, Plexus operates in the industrial, healthcare, life sciences, aerospace and defence sectors and works with highly complex customers with many regulations to comply with.

At its Livingstone site in Scotland, Plexus is working to develop two cleanroom facilities; one permanent facility and one smaller, temporary facility to enable production to commence ahead of the completion of their larger, permanent facility.

The project

Plexus originally produced a User Requirement Specification (URS) for the project as part of the tender process and chose Angstrom Technology as their solution provider, due to the range of services we offer. Utilising our expertise in cleanroom design & build, cleanroom validation, cleanroom consumables and cleanroom training, Plexus were attracted to the prospect of a single provider to manage the entire process. As such, the Angstrom team worked collaboratively to refine their URS and bring their requirements to life.

Each feature of the cleanroom was carefully designed and critical to its success. It was decided that a temporary cleanroom would be utilised as a stopgap until their larger, permanent facility was completed.

The Cleanroom

Angstrom Technology was appointed to design and build a 30m x 15m cleanroom facility, whilst at the same time producing a smaller, temporary, hybrid cleanroom.

Designed in Lancaster and built on-site in Scotland, the temporary cleanroom is a 5m x 10m hybrid structure (meaning a combination of both hardwall and softwall panels) and features HEPA filtration, achieving ISO class 7. The brief also included a softwall curtain divide to create an area separate from the main room that is used as both a change area and a pre-cleanroom inspection area. This enables the team to clean and prepare components that haven’t been manufactured in a cleanroom before they enter the main cleanroom area to prevent cross-contamination.

The Consumables

Along with the cleanroom design and build project, it was clear that a carefully selected range of cleanroom furniture would be required to make it operational. The purpose of the cleanroom is to manufacture components designed for use within the semiconductor industry. Due to the sensitive nature of their processes, furniture with antistatic properties was key, and our team were able to advise on what would be best for their processes on this basis.

Angstrom Technology’s consumables and equipment division, Cleanroomshop, offers a varied portfolio of products from a wide range of global brands.

As part of an initial visit the client made to the Angstrom Technology Lancaster office, they were able to see our showroom, which is coincidentally a hybrid cleanroom and features elements of the design specification of the preliminary cleanroom. Cleanroomshop Key Account Manager (Furniture), Lois, was on hand to discuss the furniture options and develop a list of appropriate furniture for their cleanroom requirements.

Further to this, Lois conducted an on-site visit where the cleanroom was being constructed, to collaborate with the Plexus team and evaluate appropriate furniture options. The client opted for a range of electropolished steel furniture, consisting of benches, chairs and garment cupboards including shoe storage, shelving and more. Due to the unique nature of their processes, the client also chose a selection of antistatic tables and benches that were custom-made to their bespoke requirements.

The Training

Once the physical cleanroom and consumables had been agreed upon, a selection of the client’s team attended training at Angstrom Technology’s Lancaster office. The team completed our CPD-certified ISO Cleanroom Training Course, which helps attendees control the introduction, generation, and retention of particles in cleanrooms in line with ISO standards.

Upon completion of the training course, participants were awarded a certificate of attendance for their records. The feedback received from all participants was positive and as such, Plexus suggested they may extend cleanroom training to more of their operatives upon completion of the permanent cleanroom.

Customer Quote

“We originally appointed Angstrom Technology to this project because of the support and engagement we received from the word go. We felt the team went above and beyond in terms of design work, modifications and ISO classification, and the fact they could produce a hybrid cleanroom made them stand out to us.

We opted to utilise the full su

Products & Services

Laminar Flow Cabinets

General & Smart Laboratories

Biotech & Containment Suites

Life Science & Pharmaceutical Cleanrooms

Electronics & Semiconductor Cleanrooms

Medical Cannabis Cleanrooms

Aerospace Cleanrooms

Automotive Cleanrooms

Certified ISO and EU GMP cleanroom training courses

Cleanroom Validation

Battery Dry Rooms

GMP cleanrooms

ISO 14644-1:2015 Clean rooms

Rapidbloc Cleanrooms

Ready-to-assemble cleanrooms

Rapid Room Cleanrooms

Modular cleanroom design

Location Map

Angstrom Technology Serves The Following Areas

Find Angstrom Technology in

Angstrom Technology General Description

clean rooms nationwide, clean rooms cumbria, clean rooms england environmental controls low particle envirnmoent dust free humidity free data control centres computer rooms