Telephone

Click to view

Fax

01384 563357

Website

Contact

Sales Enquiries

Email

Address

Doulton Road

Cradley Heath

West Midlands

B64 5QJ

England UK

Opening Hours

Today

08:00-17:00

View All Hours

Sunday

Closed

Monday

08:00-17:00

Tuesday

08:00-17:00

Wednesday

08:00-17:00

Thursday

08:00-17:00

Friday

08:00-17:00

Saturday

Closed

About Brooks Forgings Ltd

THE NON STANDARD SPECIALISTS

We are one of the UK’s leading manufacturers and suppliers of Standard and Special industrial fasteners to the Civil Engineering and Construction Sector.

We are certified and approved to:

Lloyd's LRQA ISO 9001 - Quality

Lloyd's LRQA ISO 14001 - Environmental

Lloyd's LRQA OHSAS 45001 - Health & Safety

Lloyd's LRQA EN 1090 EXC 3 CE

Lloyd's LRQA EN 15048 CE

National Highway Sector Scheme 3

RISQS - Rail

Whether you require a standard or bespoke component, please contact us today.

Expanding through diversification, the company has become a ‘one-stop’ service provider in the manufacture and fabrication of industrial fasteners to the civil engineering sector.

Construction components supplied:

• Holding Down Bolts

• Threaded Rebar/Rebar Bolts

• Foundation Assemblies

• Eye Bolts

• Shackles

• Hammerhead T Bolts

• U Bolts

• Special Bolts

• Galvanised Fasteners

• Tension System Components

• Torsion Bars

• Shear Reinforcement Systems

• Lifting Tackle

• Brackets

• Mooring Rings

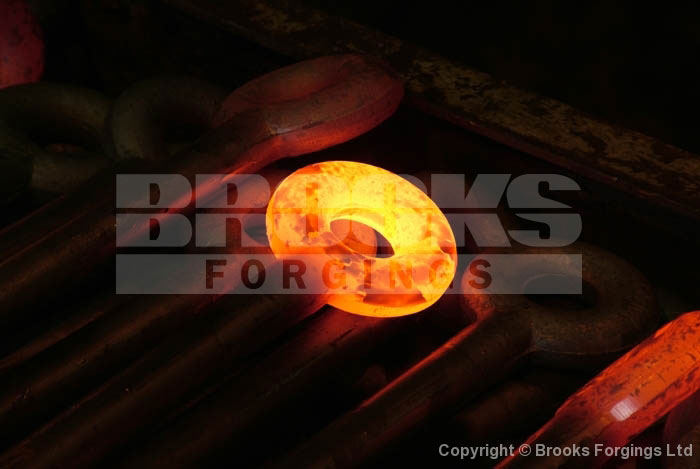

Our Manufacturing Processes include:

• Horizontal Counterblow Forging

• Upset Forging

• Drop Forging

• Open Die Forging

• Hand Forging

• Bending

• Machining

• Fabrication & Assembly

• Flash Butt Welding

• Ring Rolling

• Die Sinking

• Swaging & Pointing

• Pressing

• Sawing

• Quality Control

We have a unique mix of traditional skills, enhanced and developed alongside some of the most up-to-date forging equipment set across various production sites in the West Midlands.

It is our continued commitment to customer service that allows us to build long-term relationships with our clients. Whilst our core business centres around the forging and machining of specialist components, our many other processes and services have enabled us to offer much more.

Foundation Bolts and square plate sizes supplied from stock: Indented Foundation Bolts, J-Bolts, L-Bolts, Special Bolts, Square Square bolts to BS7419, Hammered T Bolts, Tie Bars and U bolts. Thread sizes: M6 – M100 (1/4” – 4”) with maximum lengths up to 5000mm.

Eyebolts supplied to: DIN 444, DIN 580, DIN 582, BS 4278, BS 529, BS 3974 and BS 5655 with Thread Sizes: M6 to M100 and imperial thread forms BSW, BSF, UNC and UNF. The range includes: Bow Nuts, Collared Eyebolts, Dynamo, Palm and Shackle Eyebolts, Lift Suspension Eyebolts, Round Section Eyebolts, Sling-Rod, Swivel and Adjustable Gate Eyebolts to name a selection. They are also available with increased or reduced eye thickness or with integral forged eyes.

Gallery

Videos

News

EDF energy, at Hinkley Point C, is building two new nuclear reactors, the first in a new generation of nuclear power stations that will provide low-carbon electricity for up to six million homes. The new reactors will make a significant contribution to the UK’s initiative to reduce carbon emissions.

One of the main contractors for the project awarded Brooks Forgings with the contract to manufacture and supply a range of foundation bolting assemblies for critical groundworks, in preparation for the installation of various critical infrastructure systems on the Hinkley Point C project.

Believed to be amongst the first British manufactured fastening components supplied into the project, the bolting assemblies utilise the removable DIN 7992 hammerhead t-bolt design, of which Brooks Forgings are the only British manufacturer. Ranging from M24 up to M48 in varying lengths, the bolts locate into a fabricated tube assembly that is welded to BS EN 1090 execution class 2.

Nuclear safety is a priority and extensive quality certification and documentation were required. This included but was not limited to positive material identification (PMI), ultrasonic testing (UT), magnetic particle inspection (MPI), and full mechanicals including tensile, charpy impact tests. This was backed up by an on-site audit that required all documentation and finished components to be made available for inspection.

A total of 5 quality reports were compiled, one for each size/type of foundation bolt assembly. Totalling over 200 pages each, a physical copy was supplied along with fully searchable and bookmarked PDF files to assist in locating critical information swiftly if required.

Another unique aspect of the supply was the stringent packaging requirements. Supplied in FSC and ISPM15 compliant wooden packing crates, the components were not allowed to make physical contact with the wood during transit. To prevent this and minimise rust generation during storage, special Vapour Corrosion Inhibitor (VCI) bags were used to line the interior of the wooden boxes. A full packing procedure, 3D rendered component layout, and packing list for each box was designed by Brooks and supplied for approval.

The advantages of dealing with one manufacturer are evident throughout this project. By having in-house forging, machining, and fabrication capability that is approved to EN15048 and EN1090 execution class 3 we have complete control of production and can ensure all components meet the strict quality, testing, and traceability requirements specified.

One of the main contractors for the project awarded Brooks Forgings with the contract to manufacture and supply a range of foundation bolting assemblies for critical groundworks, in preparation for the installation of various critical infrastructure systems on the Hinkley Point C project.

Believed to be amongst the first British manufactured fastening components supplied into the project, the bolting assemblies utilise the removable DIN 7992 hammerhead t-bolt design, of which Brooks Forgings are the only British manufacturer. Ranging from M24 up to M48 in varying lengths, the bolts locate into a fabricated tube assembly that is welded to BS EN 1090 execution class 2.

Nuclear safety is a priority and extensive quality certification and documentation were required. This included but was not limited to positive material identification (PMI), ultrasonic testing (UT), magnetic particle inspection (MPI), and full mechanicals including tensile, charpy impact tests. This was backed up by an on-site audit that required all documentation and finished components to be made available for inspection.

A total of 5 quality reports were compiled, one for each size/type of foundation bolt assembly. Totalling over 200 pages each, a physical copy was supplied along with fully searchable and bookmarked PDF files to assist in locating critical information swiftly if required.

Another unique aspect of the supply was the stringent packaging requirements. Supplied in FSC and ISPM15 compliant wooden packing crates, the components were not allowed to make physical contact with the wood during transit. To prevent this and minimise rust generation during storage, special Vapour Corrosion Inhibitor (VCI) bags were used to line the interior of the wooden boxes. A full packing procedure, 3D rendered component layout, and packing list for each box was designed by Brooks and supplied for approval.

The advantages of dealing with one manufacturer are evident throughout this project. By having in-house forging, machining, and fabrication capability that is approved to EN15048 and EN1090 execution class 3 we have complete control of production and can ensure all components meet the strict quality, testing, and traceability requirements specified.

UK

UK Ireland

Ireland Scotland

Scotland London

London