Time and date

CONSTRUCTION DIRECTORY

Trenchdare Engineering Ltd Contact Details

Telephone

Click to view

Fax

0114-275 0309

Website

Contact

Mr Richard Hall

Email

Address

Viking Works

Effingham Road

Effingham Road

Sheffield

South Yorkshire

S4 7YS

England

Opening Hours

Wednesday

08:00 am-05:30 pm

Monday

08:00 am-05:30 pm

Tuesday

08:00 am-05:30 pm

Wednesday

08:00 am-05:30 pm

Thursday

08:00 am-05:30 pm

Friday

08:00 am-01:00 pm

Saturday

Closed

Sunday

Closed

Other Dates

For out of hours assistance / enquiries ring 07880 793 738 - Contact Richard Hall - Director

About Trenchdare Engineering Ltd

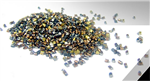

Trenchdare Engineering has been in business since 1984, based in Sheffield producing high quality cut wire pellets and has the BS EN ISO 9001:2008 accreditation. We are currently the largest producer of cut wire pellets in the UK today in both High and Medium Tensile Steel and also Stainless Steel for both Shot Blasting and Dry Media Polishing applications.

State-of-the-art equipment has been installed for production of conditioned cut wire pellets both in Carbon and Stainless Steel for shot peening. We currently offer the widest range of high quality metallic abrasive products available in the UK.

Product Range

Cut Wire Pellets

Standard pellets are available in three types:

High Tensile Carbon Steel Pellets

High Tensile Carbon Steel Pellets are most used in applications where a more tenacious type of contamination such as heavy scale from heat treatment or forging and sand from heavy casting processes are encountered.

Medium Tensile Carbon Steel Pellets

Medium Tensile Carbon Steel Pellets are used for cleaning applications such as fabrications, plate and sections where its exceptional life as well as its cleaning abilities are appreciated by those in the construction and contract cleaning industries producing a rounded profile suitable for surface coating.

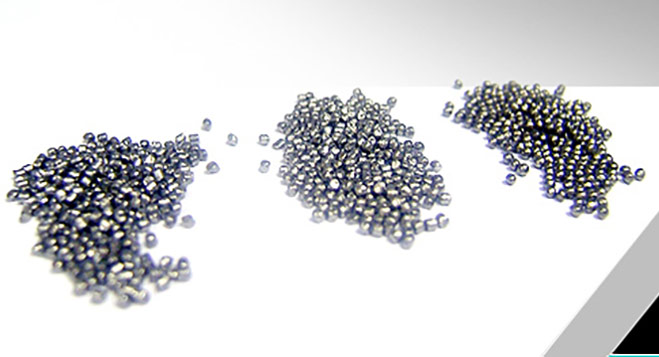

Stainless Steel Cut Wire Pellets

Stainless steel cut wire pellets are used in applications where reduction of ferrous contamination or where the cleaning of an Aluminium type Alloy or Stainless Steel casting or forging is required where a dense, solid and long lasting media above 0.7mm in size is needed (below 0.7mm particale size, sast Stainless steel shot is also available).

Conditioned Cut Wire Pellets

Both Carbon and Stainless steel pellets can be produced on site in a variety of size and hardness to G1, G2 and G3 levels of conditioning to suit individual customers needs and specifications.

Cast Steel Shot

Cast steel shots are avilable from stock in both high and low Carbon analysis types in all popular sizes for those customers whose applications is suited by a media whose breakdown produces a mixture of particle sizes. These products produce a rounded profile in use.

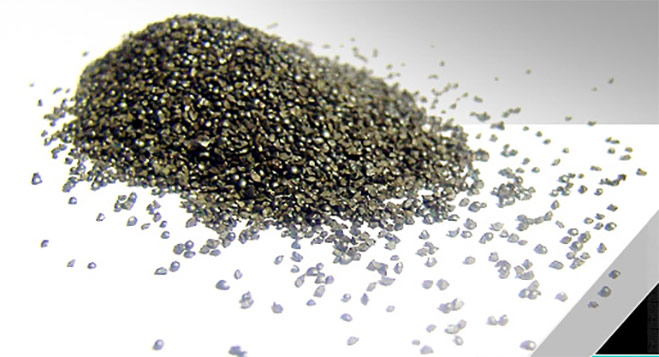

Cast Steel Grits

Cast steel grits are available in standard, medium and high hardness in all popular sizes to meet the requirements of customers who require a media with a more aggressive action than shot and producing an angular surface finish.

Cast Stainless Steel Shots

Cast Stainless steel shots are available in all sizes for customers looking to blast a Stainless, Aluminium or other Alloy type surfaces without the risk of ferrous contamination associated with the use of either cast steel or chilled iron abrasives.

Chilled Cast Iron Grit

Chilled iron grits are available from stock to meet requirements of customers who need a hard, fast cleaning media producing a sharp angular type profile for use in compressed air powered blast rooms and booths.

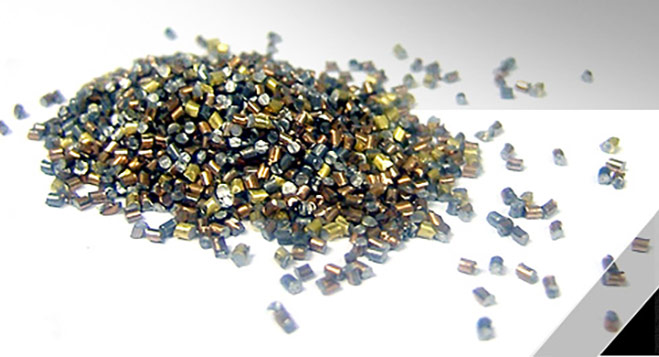

Cut Wire Pellet / Cast Steel Shot or Grit Mixes

Abrasive mixes can be produced on site to meet individual customer specifications, resultant surface finish is dependant on mix constituents.

Ballast Materials

Ballast type materials can be produced for a variety of applications:

Fibres for a variety of end use requirements:

Our Services

We are also leading stockists of most other types of shot blast media and machine parts.

State-of-the-art equipment has been installed for production of conditioned cut wire pellets both in Carbon and Stainless Steel for shot peening. We currently offer the widest range of high quality metallic abrasive products available in the UK.

Product Range

Cut Wire Pellets

Standard pellets are available in three types:

- High Tensile Carbon Steel

- Medium Tensile Carbon Steel

- Stainless Steel

High Tensile Carbon Steel Pellets

High Tensile Carbon Steel Pellets are most used in applications where a more tenacious type of contamination such as heavy scale from heat treatment or forging and sand from heavy casting processes are encountered.

Medium Tensile Carbon Steel Pellets

Medium Tensile Carbon Steel Pellets are used for cleaning applications such as fabrications, plate and sections where its exceptional life as well as its cleaning abilities are appreciated by those in the construction and contract cleaning industries producing a rounded profile suitable for surface coating.

Stainless Steel Cut Wire Pellets

Stainless steel cut wire pellets are used in applications where reduction of ferrous contamination or where the cleaning of an Aluminium type Alloy or Stainless Steel casting or forging is required where a dense, solid and long lasting media above 0.7mm in size is needed (below 0.7mm particale size, sast Stainless steel shot is also available).

Conditioned Cut Wire Pellets

Both Carbon and Stainless steel pellets can be produced on site in a variety of size and hardness to G1, G2 and G3 levels of conditioning to suit individual customers needs and specifications.

Cast Steel Shot

Cast steel shots are avilable from stock in both high and low Carbon analysis types in all popular sizes for those customers whose applications is suited by a media whose breakdown produces a mixture of particle sizes. These products produce a rounded profile in use.

Cast Steel Grits

Cast steel grits are available in standard, medium and high hardness in all popular sizes to meet the requirements of customers who require a media with a more aggressive action than shot and producing an angular surface finish.

Cast Stainless Steel Shots

Cast Stainless steel shots are available in all sizes for customers looking to blast a Stainless, Aluminium or other Alloy type surfaces without the risk of ferrous contamination associated with the use of either cast steel or chilled iron abrasives.

Chilled Cast Iron Grit

Chilled iron grits are available from stock to meet requirements of customers who need a hard, fast cleaning media producing a sharp angular type profile for use in compressed air powered blast rooms and booths.

Cut Wire Pellet / Cast Steel Shot or Grit Mixes

Abrasive mixes can be produced on site to meet individual customer specifications, resultant surface finish is dependant on mix constituents.

Ballast Materials

Ballast type materials can be produced for a variety of applications:

- Ships Ballast

- Counter Balance Weight

- Concrete Aggregates

- Foundations

- Safe or Strong Room Security Doors and Walls

- Sound Proofing or Vibration Damping, etc.

Fibres for a variety of end use requirements:

- Chemical

- Ballast

- Refractory Fillers

- Safe and Security Walls, etc.

Our Services

We are also leading stockists of most other types of shot blast media and machine parts.

- Conditioning Facilities

Pellets cut on-site can be conditioned to customers specification at our state-of-the-art conditioning facility. - Laboratory Facility

Our fully equipped laboratory with facilities for tensile hardness, size and durability testing. - Machine Surveys

Customers shot blast machines can be examined and surveyed for the best economical usage of abrasives supplied with on-site size distribution analysis facilities for immediate exchange of information.

Gallery

|

Click to close

|

Team

| Name | Role | Telephone | |

| Richard Hall | Sales Director | sales@trenchdare.co.uk | 00 44 114 2 700 893 |

| Philip Hall | Managing Director | sales@trenchdare.co.uk | 00 44 114 2 700 893 |

| Susan Hall | Finance Director | sales@trenchdare.co.uk | 00 44 114 2 700 893 |